Revolutionizing Architectural Design through Manufacturing Models

In the dynamic world of architecture, precision, efficiency, and innovation are paramount. At the core of achieving these objectives are manufacturing models, tools that bridge the gap between conceptual design and practical execution. This article explores the multifaceted role of manufacturing models in architecture, emphasizing their importance in enhancing the workflow, improving accuracy, and fostering collaboration among architects, engineers, and contractors.

Understanding Manufacturing Models

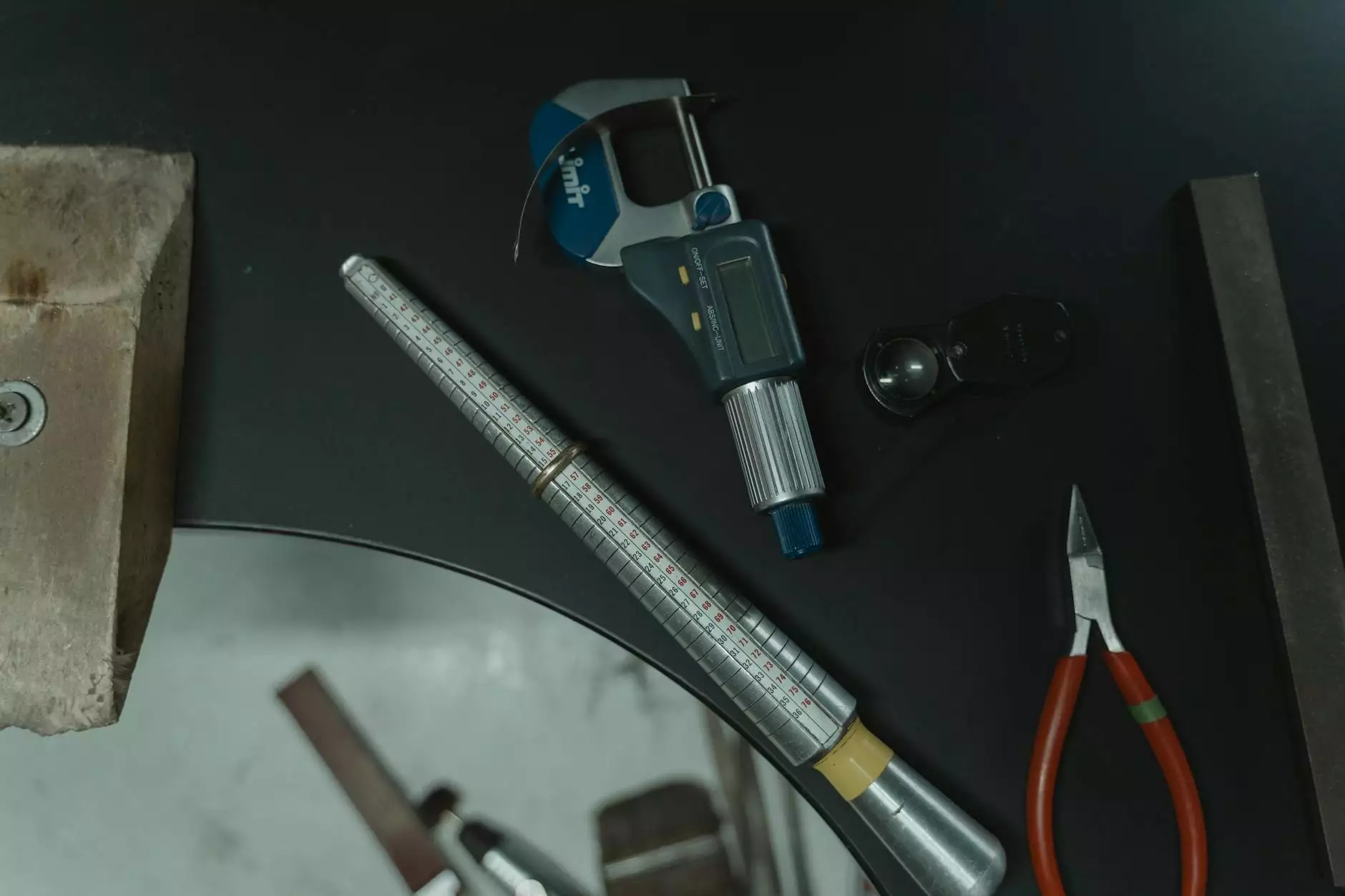

Manufacturing models represent a pivotal complement to architectural practice. These models are tangible or digital representations that communicate design intentions, facilitate discussions, and serve as a prototype during the construction phase. With the rise of advanced technology, such as 3D printing and computer-aided design (CAD), architects can create more sophisticated and detailed models, allowing for greater visual clarity and insights during the design process.

The Evolution of Manufacturing Models in Architecture

Historical practices in architecture relied heavily on traditional methods of representation. Early drafts, sketches, and hand-crafted physical models conveyed ideas but often lacked the precision required for modern standards. As technology has advanced, so too have manufacturing models. The transition to digital platforms has enabled architects to:

- Visualize Complex Designs: 3D modeling software allows for intricate designs that are challenging to represent on paper.

- Simulate Functionality: Architects can create interactive models that simulate how a space will function in real-life scenarios.

- Facilitate Changes and Iterations: Digital models allow for faster changes, enabling architects to adapt designs based on feedback swiftly.

The Benefits of Using Manufacturing Models

Utilizing manufacturing models in architectural practice offers a myriad of benefits that enhance both the design and construction processes:

1. Enhanced Accuracy and Detail

One of the significant advantages of manufacturing models is their ability to provide unmatched accuracy. In architecture, even the smallest discrepancy can lead to costly mistakes. Therefore, creating a model that details every aspect of a design ensures that:

- Measurements are precise, reducing the risk of errors during construction.

- Materials can be visualized in their full scale, ensuring proper selections.

- Architectural elements harmonize seamlessly, resulting in a cohesive design.

2. Improved Collaboration Among Stakeholders

Architecture is inherently collaborative, involving architects, engineers, contractors, and clients. Manufacturing models facilitate communication by providing a common reference point for stakeholders. This improves collaboration in several ways:

- Visual Communication: Models act as visual aids that can help convey complex ideas that may be misunderstood through verbal or written descriptions.

- Reduced Misunderstandings: By providing everyone with the same model, the likelihood of misinterpretation diminishes, creating a smoother workflow.

- Engagement of Clients: Clients can better understand and visualize their future spaces when presented with detailed models, fostering trust and satisfaction.

3. Streamlined Workflow and Efficiency

Adopting manufacturing models can lead to significant improvements in efficiency throughout the design and construction phases:

- Early Problem Detection: Digital models often include the capability for simulation, allowing for the early identification of potential conflicts or problems.

- Faster Approvals: Stakeholders are more likely to approve designs when they can visualize them in a model format.

- Facilitated Fabrication: Models can be directly integrated into manufacturing processes, simplifying the transition from design to construction.

Key Technologies Used in Manufacturing Models

The technological landscape surrounding manufacturing models is diverse and ever-evolving. Several key technologies are particularly influential in shaping the future of architectural design:

1. 3D Printing

3D printing has revolutionized the way architects create physical models. This technology enables the accurate reproduction of designs in three dimensions, showcasing intricate details that traditional model-making techniques often struggle to replicate. The benefits include:

- Speed: Models can be produced rapidly, allowing for quick iterations and modifications.

- Cost-Effectiveness: As technology becomes more accessible, the cost of producing models decreases, making it feasible for smaller firms to utilize.

- Material Diversity: Various materials can be used in 3D printing, providing architects with options to showcase different finishes and textures.

2. Building Information Modeling (BIM)

BIM represents a game-changer in architectural design, offering a digital representation of physical and functional characteristics of a facility. With BIM, architects can:

- Create Comprehensive Models: Integrate detailed data regarding geometry, spatial relationships, and geographic information.

- Coordinate Efforts Among Disciplines: Facilitate collaboration between multiple stakeholders, ensuring everyone's input is considered in the design process.

- Utilize Real-Time Data: Allow for the updating of models based on new information, which can include budget changes or updated client requests.

Case Studies: Successful Implementation of Manufacturing Models

Numerous architectural firms have successfully integrated manufacturing models into their workflows with impressive results. Here are a few notable examples:

1. The High Line in New York City

The transformation of the High Line, an elevated railway into a public park, required innovative design solutions. By utilizing manufacturing models, the team was able to:

- Visualize the park's interaction with the surrounding urban landscape.

- Simulate pedestrian movement and traffic flow to maximize usability.

- Engage community members through models that showcased proposed changes, fostering public support.

2. Sydney Opera House Renovation

The iconic Sydney Opera House underwent renovations to enhance its facilities and ensure longevity. Architects used manufacturing models to:

- Test new designs in a scaled model to assure aesthetic and functional alignment with the original structure.

- Evaluate materials for sustainability and weather resistance.

- Facilitate dialogue between designers and engineers ensuring structural integrity was preserved during updates.

The Future of Manufacturing Models in Architecture

As we look to the future, the role of manufacturing models will undoubtedly grow. We can expect to see a few prominent trends:

- Increased Integration with Artificial Intelligence: Predictive algorithms will streamline the design process, providing architects with recommendations based on historical data and current trends.

- Customization: With advancements in technology, more tailored solutions will emerge, allowing for personalized designs that cater to specific needs and preferences.

- Greater Sustainability: Innovations will focus on sustainable materials and methods, further reducing the architectural industry's carbon footprint through efficient design and fabrication.

Conclusion

In conclusion, manufacturing models are not just a trend but an integral part of modern architecture that enhances design, improves collaboration, and streamlines processes. With the evolution of technologies such as 3D printing and BIM, the capabilities of manufacturing models are set to expand even further, positioning architectural firms for success in a competitive landscape. Embracing these models is essential, not only for improving project outcomes but also for generating innovative solutions that cater to the demands of today and tomorrow.

To explore more about manufacturing models and their applications in architecture, visit architectural-model.com.